UL94 V-0 (combined with Kapton50H)

* Kapton® is a registered trademark of DuPont in the U.S.

Product Overview

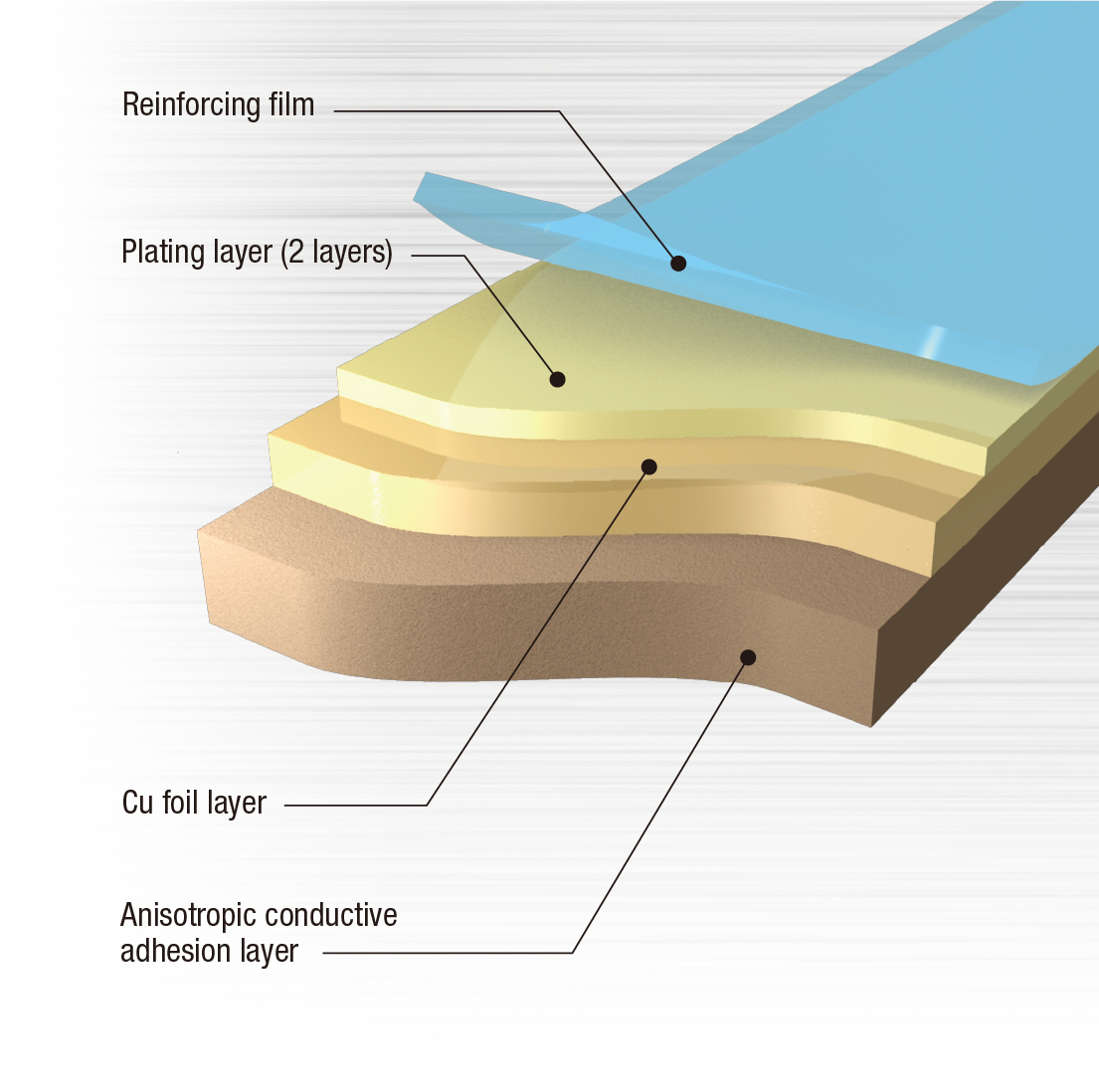

For using a Cu foil shielding film for high speed signal transmission, this grounding film can maintain a lower resistance value. High reliability is realized through alloying of the special conductive fillers used in the anisotropic conductive adhesive and the Cu foil layer of the Cu foil shielding film.

* We do not guarantee any combination with other products than TATSUTA-manufactured shielding films. This product is exclusive to Cu foil-based shielding films.

Features

-

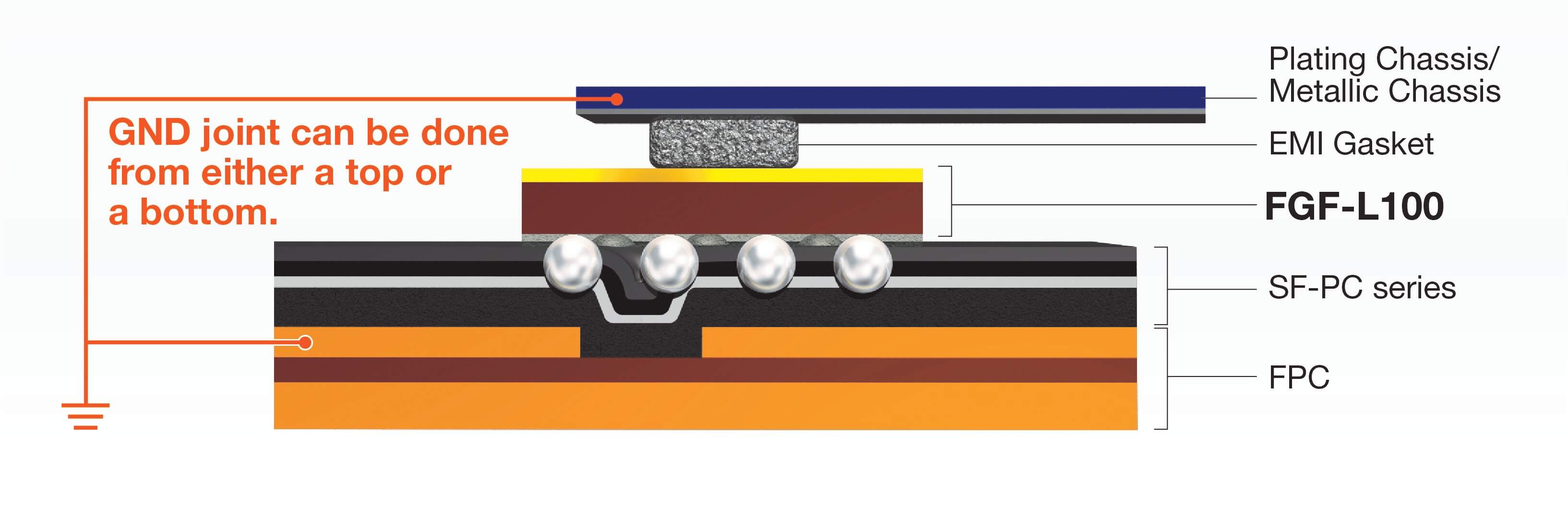

Enables high-density wiring of boards

GND for external connection can be secured in the FPC wiring area.

-

Excellent joint reliability

As the conductive fillers contained in the anisotropic conductive adhesive is alloyed with the Cu foil layer of the Cu foil shielding film, stable joint resistance is achieved even after various environmental tests.

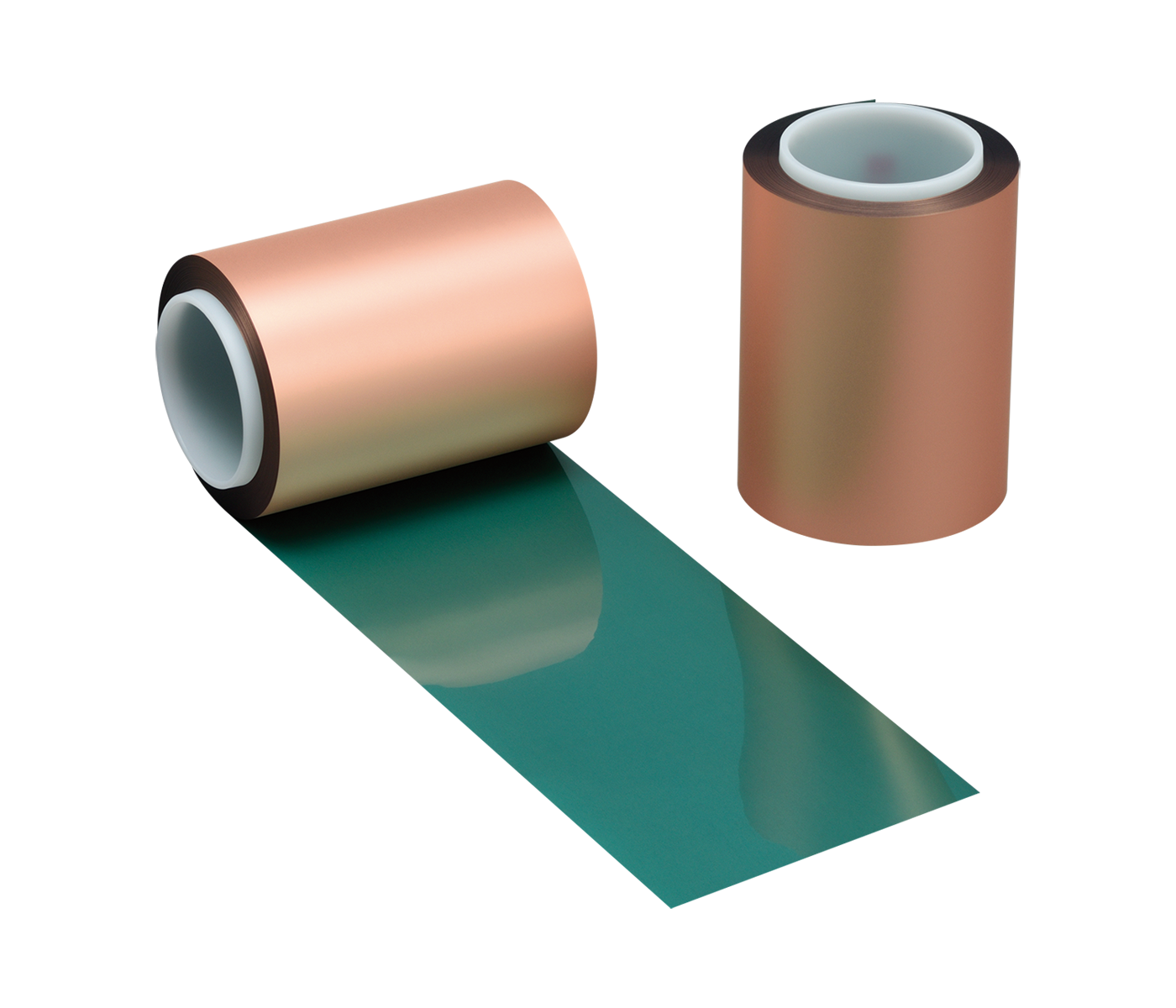

Main specifications

| Item | FGF-L100 | |

|---|---|---|

| Thickness Reinforcing film | 64um | |

| Total thickness (after press) | 29um | |

| Plating layer | About 0.5um | |

| Cu foil layer | 6um | |

| Anisotropic conductive adhesion layer | 23um | |

| Joint resistance * FGF size: 2.5mm x 2.5mm |

0.5Ω | |

| Peeling strength | Over 3.0N/cm | |

| Shelf life (keep cool) | 6 months | |

Examples of Use

Application image

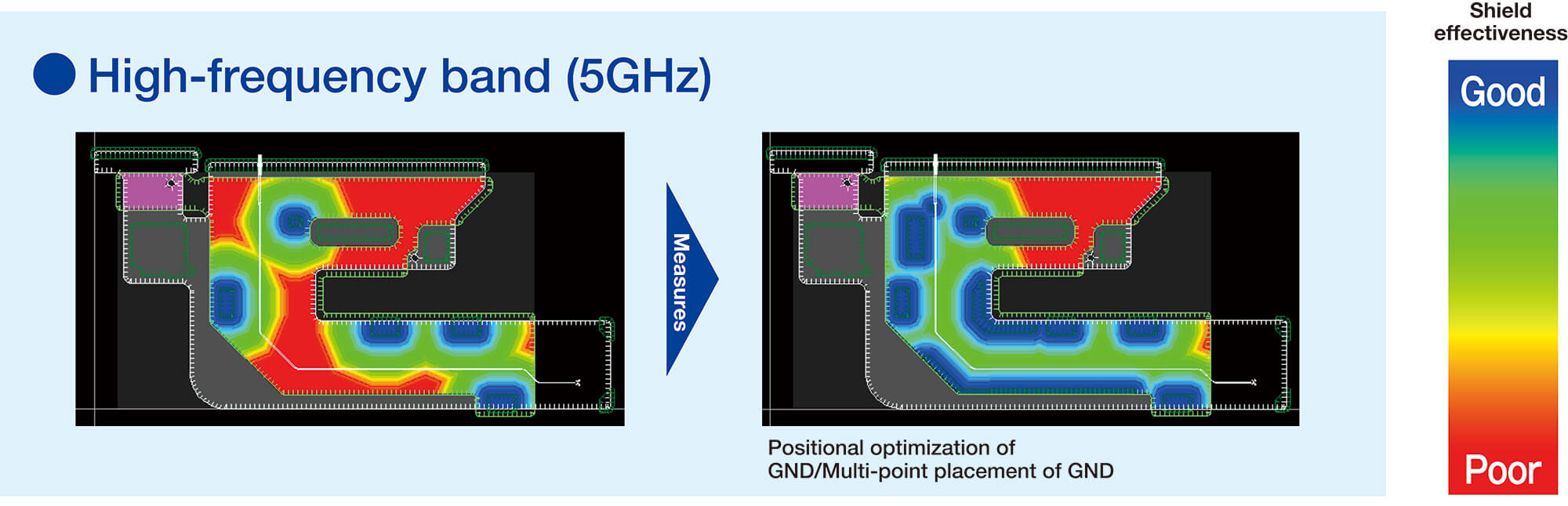

Multi-point placement of GND can make the shield effectiveness develop more effectively.

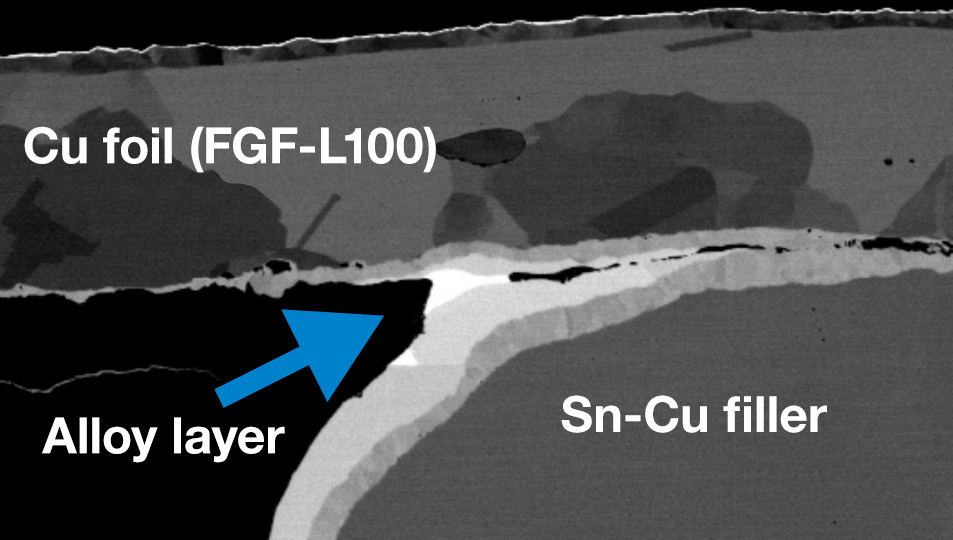

Alloying of the Cu foil layer of the Cu foil shielding film and the conductive fillers of the FGF-L100 improves connectivity and achieves a stable resistance value.

-

-

Cross-sectional view

-

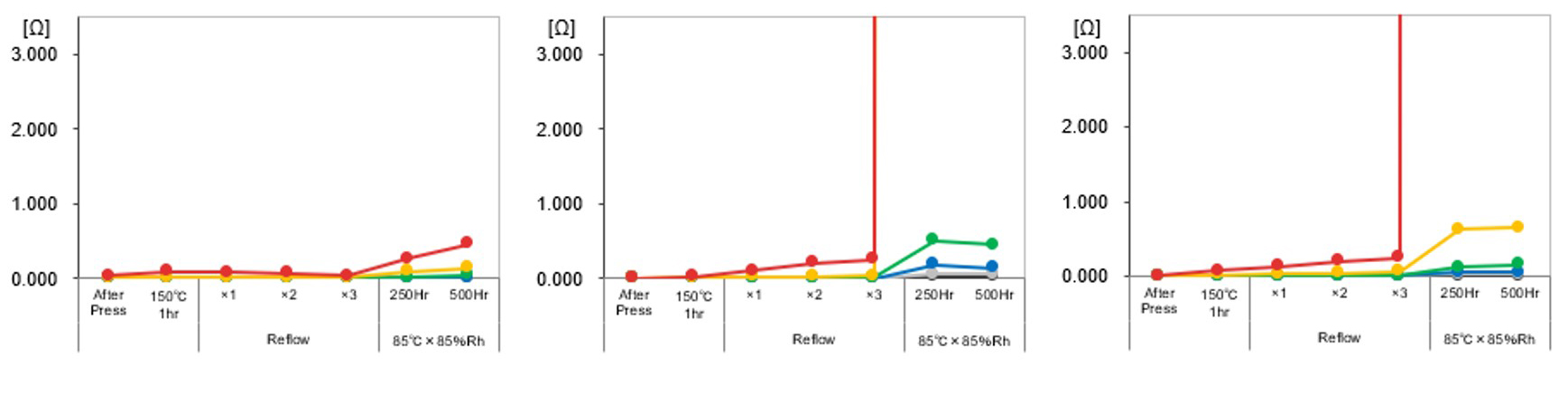

Reference data

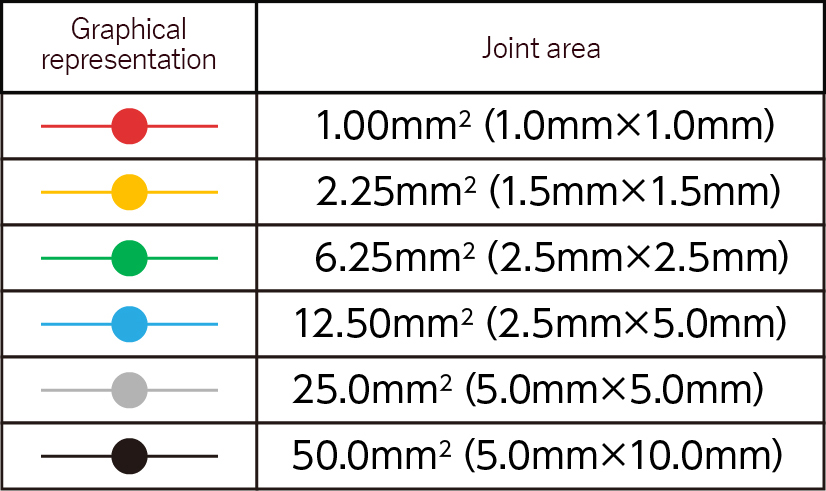

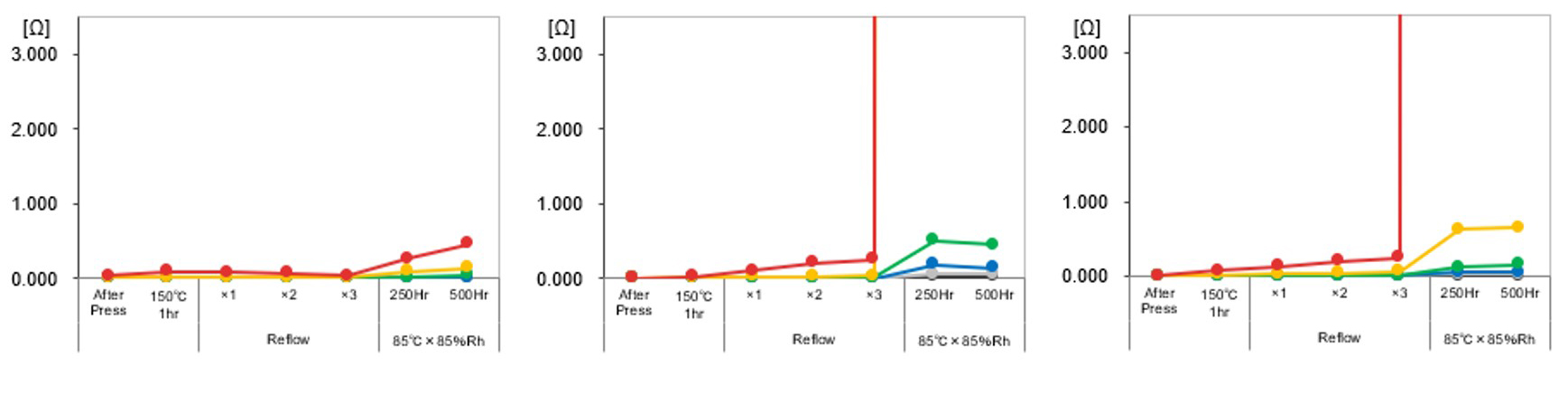

Joint resistance value(five reflows)

- ・Press conditions: 170℃ x 3MPa x 30min

- ・Shielding film: SF-PC3300-C

Joint resistance value(85℃85%Rh500)

- ・Press conditions: 170℃ x 3MPa x 30min

- ・Shielding film: SF-PC3300-C

* Above data and numerical values are all actual measurement values, not guaranteed values.