Shielding film for high-speed signal transmission FPC (bake-less)

WILMINA®

SF-PC®3500P2-C

UL94 VTM-0 (combined with Kapton50H)

* Kapton® is a registered trademark of DuPont in the U.S.

Product Overview

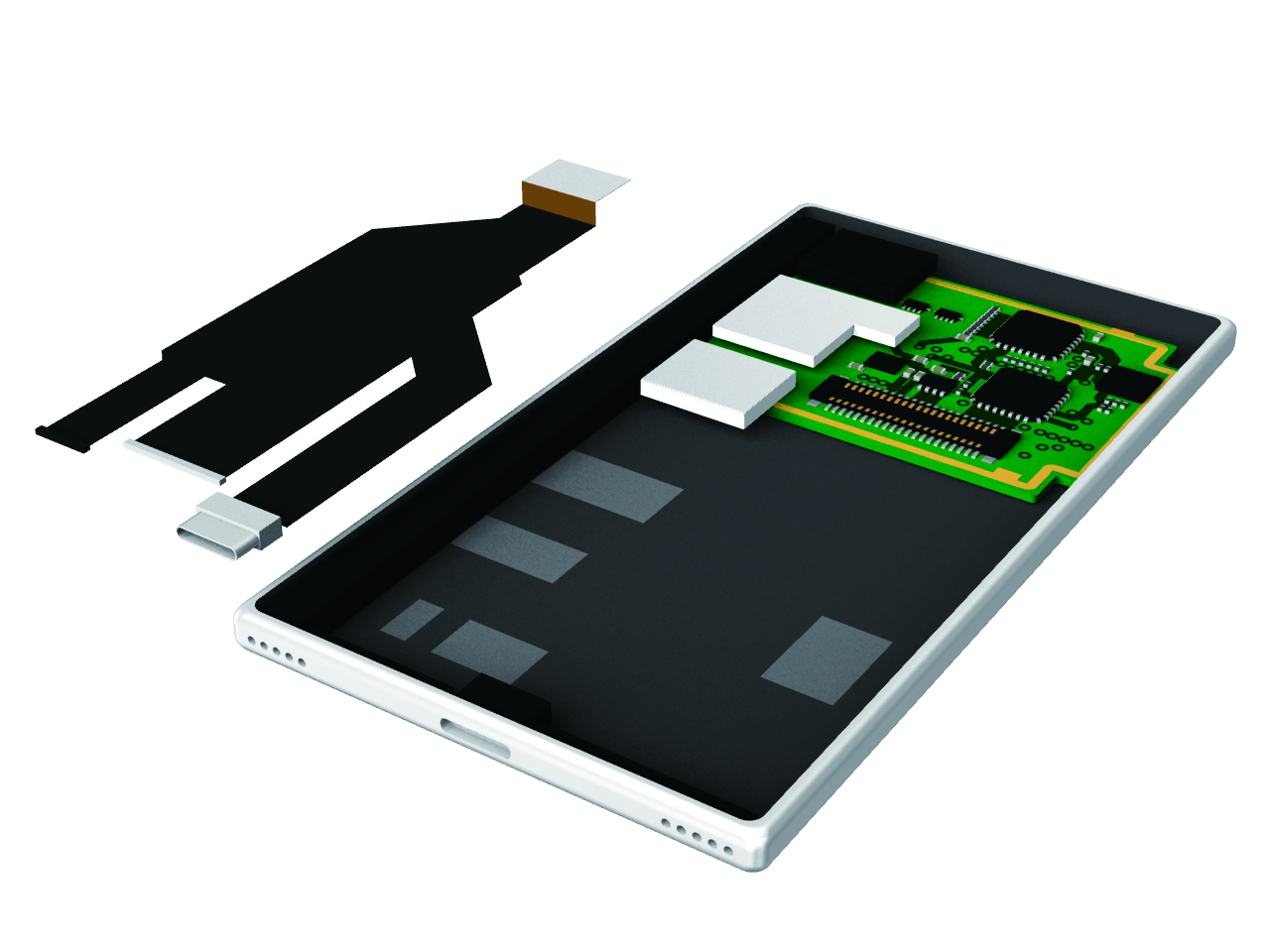

When Cu foil-based shielding films are used, baking may be required before processing and before reflowing depending on FPC specifications, but the SF-PC3500P2-C can skip the baking process. In the case of shielding films using conventional Cu foil, outgassing from FPC during reflowing is shielded by the Cu foil layer, which sometimes results in a swollen appearance. The SF-PC3500P2-C, which is provided with specially perforated Cu foil, allow the outgas to escape and suppress the swelling. While reducing process loads, this product can achieve high shield performance.

Features

-

Process simplification

By using specially perforated Cu foil, baking before processing shielding films and before reflowing can be skipped, so that processes can be simplified.

-

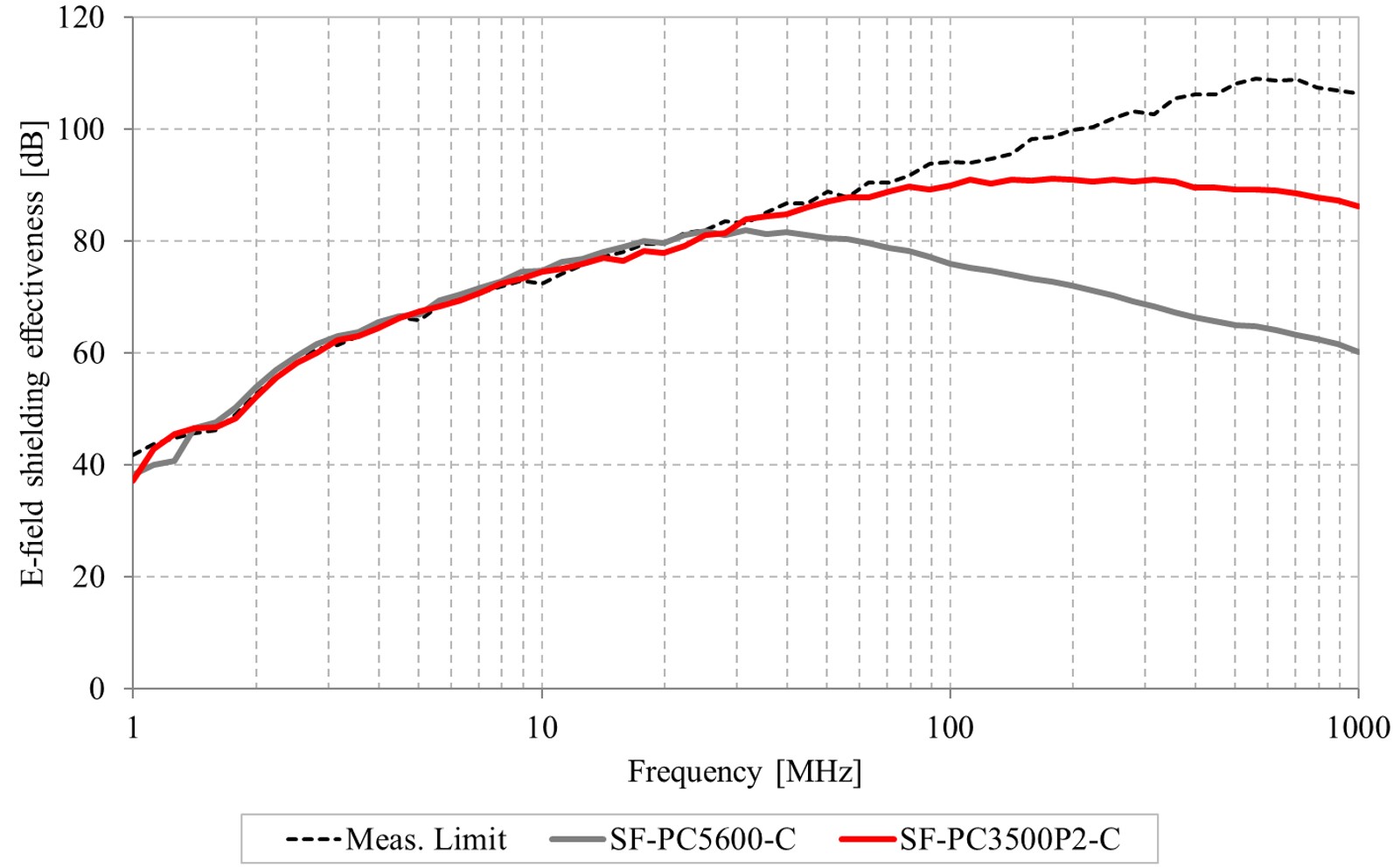

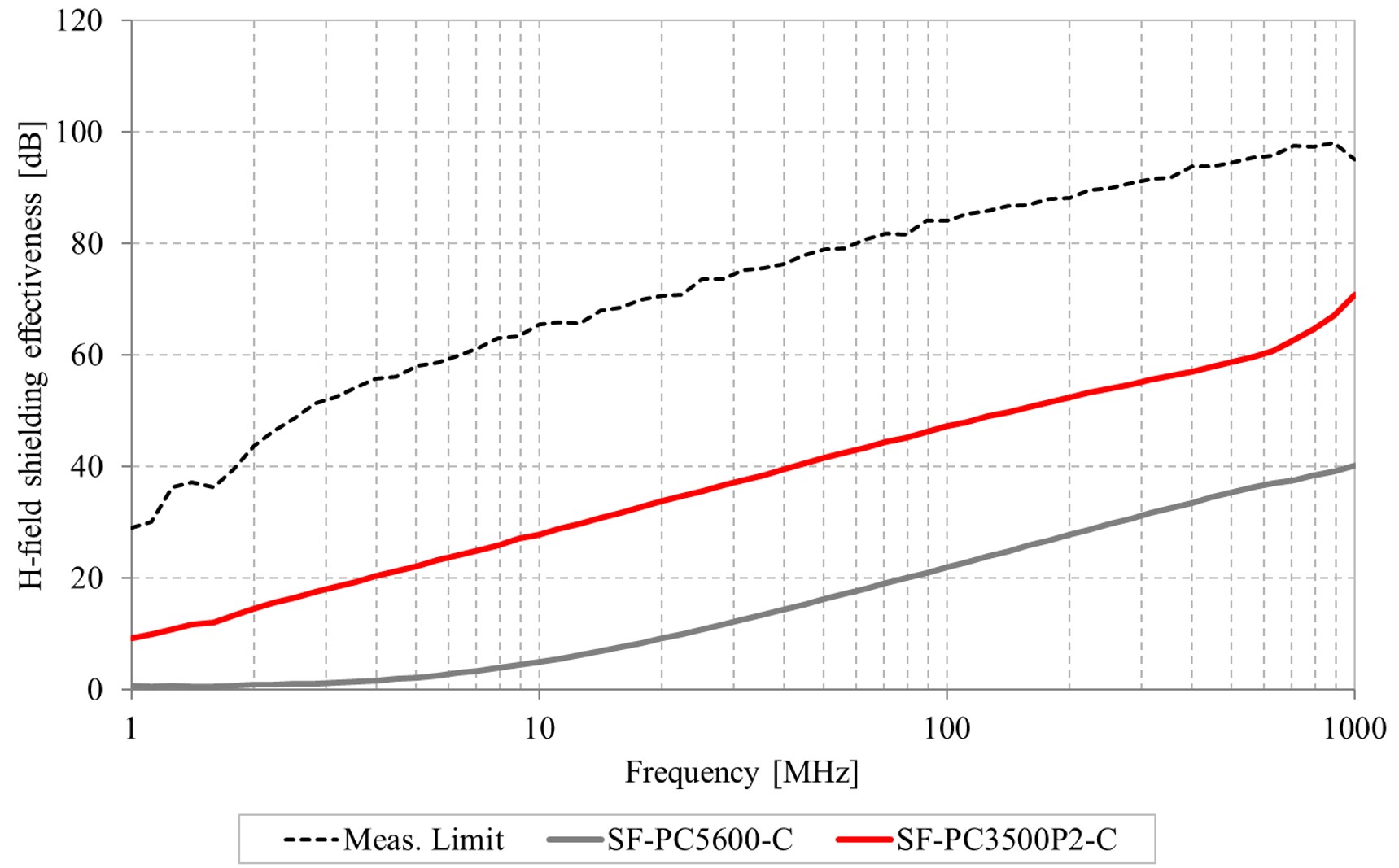

High shield performance

Offers top-class performance among all TATSUTA products.

SF-PC3500P2-C: Over 80dB/1GHz, Over 75dB/10GHz

Main specifications

| Item | SF-PC3500P2-C | |

|---|---|---|

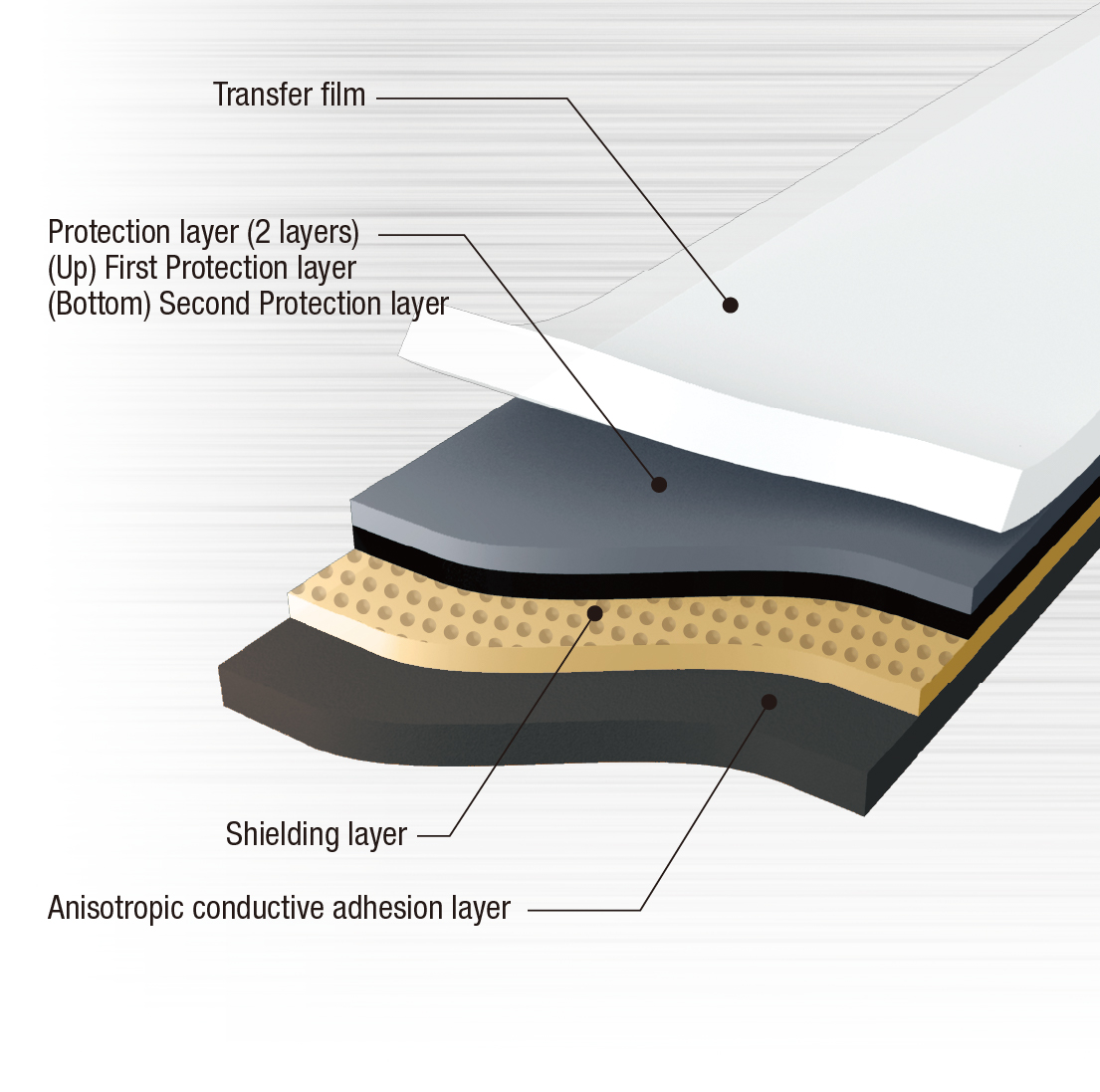

| Thickness Transfer film | 38um | |

| Total thickness (after press) | 18um | |

| Protection layer | 6um | |

| Shielding layer | 2um | |

| Anisotropic conductive adhesion layer | 10um | |

| Peeling strength | Over 3.0N/cm | |

| Shelf life | 6 months | |

Reference data

Reflow resistance evaluation

| Grade | Board baking | Board moisture absorption | Shielding film press conditions |

Moisture absorption | Baking | Swelling after reflowing | ||

|---|---|---|---|---|---|---|---|---|

| One reflow | Two reflows | Three reflows | ||||||

| SF-PC3500P2 | 135℃ 60min | None | Vacuum quick at 170℃ 10sec + 180sec |

None | 135℃ 60min | ○ | ○ | ○ |

| SF-SF-PC3300 | ○ | ○ | ○ | |||||

| SF-PC3500P2 | None | 40℃ 90% 96Hr |

Vacuum quick at 170℃ 10sec + 180sec |

None | None | ○ | ○ | ○ |

| SF-PC3300 | ☓ | ☓ | ☓ | |||||

| SF-PC3500P2 | None | None | Vacuum quick at 170℃ 10sec + 180sec |

65℃ 90% 24Hr |

None | ○ | ○ | ○ |

| SF-PC3300 | ☓ | ☓ | ☓ | |||||

* After pressing shielding films, oven curing is performed at 150°C for 60 min.

* Above data and numerical values are all actual measurement values, not guaranteed values.